Application industry

RETURNService support

RETURNBlog dynamics

RETURNTalent recruitment

RETURNContact us

RETURNBeverage, food fast-selling packaging

In the beverage and food packaging industry, product safety and quality are the most important factors for consumers. As a professional manufacturer of hot melt adhesives, we know that these industries have extremely strict requirements for bonding materials. Therefore, we are committed to providing safe and efficient bonding solutions to meet these high standards.

In the field of beverages and food, product hygiene standards are very important. Our hot melt adhesive products use food-grade raw materials to ensure that they are non-toxic and tasteless, and will not cause any pollution to food or beverages. They are widely used in bottle cap sealing, label pasting and other links, can withstand various temperature changes without falling off, to ensure the integrity and safety of products in the entire supply chain.

Material composite, automotive interior

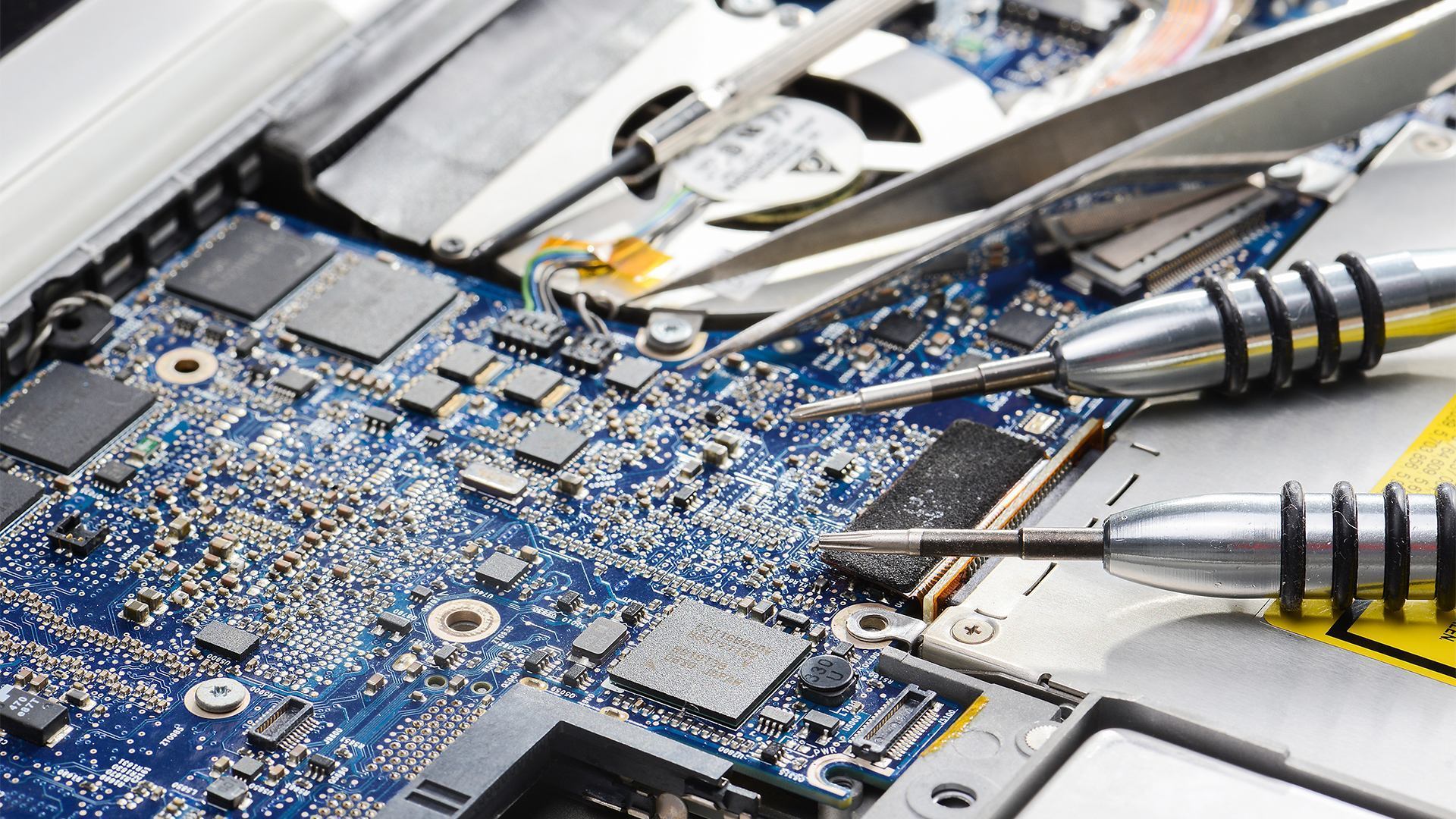

Electronics and Crafts Industry

Dust filtration, sewage treatment

For the wastewater treatment industry, our polyurethane and epoxy adhesives are an integral part of treatment equipment because of their excellent chemical resistance and mechanical strength. They can not only effectively fix various fillers and membrane materials, but also resist harsh water quality conditions, such as pH changes, high salinity, etc., to ensure the long-term stable operation of the sewage treatment system.

We always put the safety and high quality of our products in the first place, and continue to develop and innovate to meet the growing needs of the dust filtration and sewage treatment industry. Our goal is to provide high-performance bonding solutions to help customers improve product quality, enhance market competitiveness, and ultimately win the trust and support of consumers.

In addition, we also pay attention to the environmental protection of our products. All adhesives are made of non-toxic and harmless raw materials, which meet international environmental protection standards. This not only helps to protect the environment, but also brings a good social image and economic benefits for the enterprise.